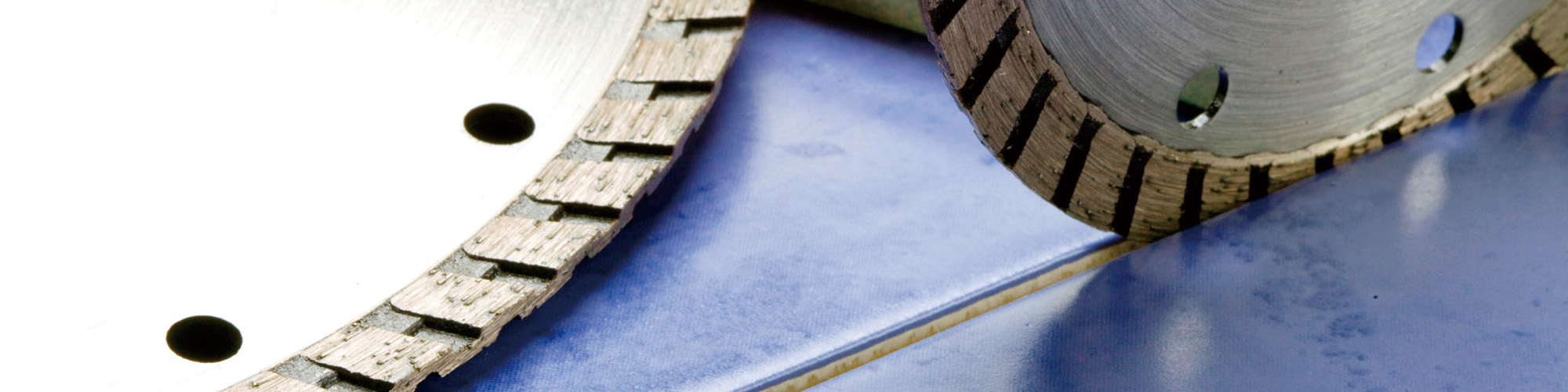

What saw blade for cutting tiles

Time:2019-04-17 13:08:04Browse:0

This article will introduce you to the knowledge of diamond saw blades, diamond saw blade purchase techniques and the top ten brands of diamond saw blades.

Classification of diamond saw blades

More and more industries are using diamond saw blades in the production process. With the integration of the industry, the types of diamond saw blades are becoming more and more detailed.

First, according to the manufacturing process

1. Sintered diamond saw blade: divided into cold pressing sintering and hot pressing sintering, which are pressed and sintered.

2. Welded diamond saw blade: divided into high frequency welding and laser welding. The high frequency welding welds the cutter head and the base body through a high temperature melting medium. The laser welding melts the contact edge of the cutter head and the base by a high temperature laser beam to form a metallurgical bond. .

3. Electroplated diamond saw blade: The cutter head powder is attached to the substrate by electroplating.

Second, by appearance

1. Continuous edge saw blade: continuous sawtooth diamond saw blade, generally made by sintering method. Commonly used bronze binder is used as the base carcass material. Water must be added during cutting to ensure the cutting effect, and the type of slit is cut by the laser.

2, the cutter head saw blade: the sawtooth is broken, the cutting speed is fast, suitable for dry and wet cutting methods.

Our company has won the trust of customers with good faith, achieved good reputation with customers for quality, and solved difficult problems for customers with professionalism. While strengthening the cooperation with the market, we constantly enhance our own cultivation, continuous innovation, and sales of well-known brand tools. I believe that in the near future, we can provide customers with more comprehensive and professional products. Our company is dedicated to providing you with services!

Previous: Saw blade installation process