Saw blade installation process

Time:2019-04-15 11:44:04Browse:0

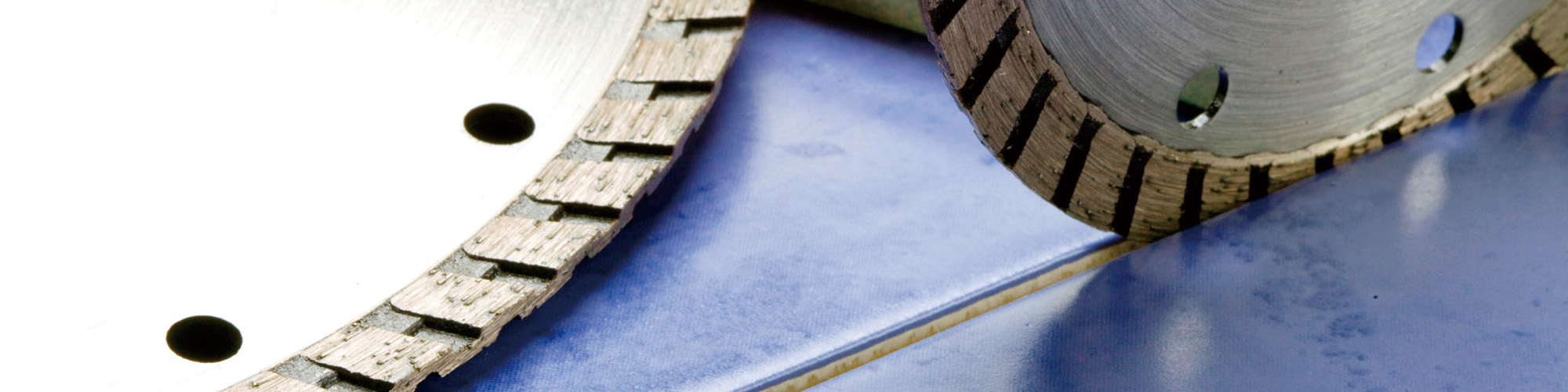

Metal Circular Saw Machine Tool - Circular Saw Blade Set

Keep the flange surface clean and clean, and do not install the reverse direction of the circular saw blade. The side with the trademark is facing upwards. The flange should be locked with M16 screws.

Clean the circular saw blade and peripheral parts, fix the parts with screws to prevent looseness, especially the circular saw blade cover, keep the circular saw blade and the guide rail clean, and gently rotate the hand to ensure the smooth rotation of the saw blade. can.

When installing the wire brush, it must be ensured that the circular saw blade is aligned.

When adjusting the front end of the wire brush, the circular sawtooth bag is covered.

When the circular saw blade is in the process of turning, it may be dangerous if it is touched by hand. Please wait until the equipment is completely stopped before opening the blade cover. When replacing the saw blade, the power must be cut off.

Metal circular saw blade sawing stroke setting

The forward end of the circular saw blade, the proximity switch on the lateral clamping seat and the saw blade cover have any unchecked parts. It must be confirmed that all round materials can be set correspondingly, and it is not necessary to adjust the position of the retracted end to be fixed. The position of the last end of the adjustment is also fixed, and cannot be adjusted. (Note that this scale cannot be used when it is square or shaped steel, so the saw blade may be damaged according to this)

What are the common problems with saw blades?

Frequently Asked Questions Cause Solution The incision has a bristles shape and the number of teeth is incorrect. The teeth are grinded according to the material being cut. The number of teeth is not sharp enough or the teeth are re-grinded. The saw blade is cut with a different material. Do not check the machine fixture serrated with chip cleaning, check whether the number of cutting teeth is suitable for the sawtooth has been blunt or broken teeth re-grinding the saw blade sawing material is not vertical feeding frame collision and shaking positioning is not allowed, the machine is assembled without calibration Always check the condition of the rack and the positioning ruler.

Correct the level of the machine. Use a saw blade with a large yaw degree to erect it to avoid the deformation of the material caused by the yaw caused by the pressure deformation. The material selection speed is too fast and the number of teeth is incorrect. And the wall thickness selects the appropriate number of teeth and the lower knife speed. The saw blade bursts or the broken tooth saw blade does not lock the inspection flange.

Lock the screw and cut the material without clamping. Check the machine tool. The blade feed speed is unstable. Use the manual pipe cutter. The feed speed of the lower knife should be evenly fast. The feed speed is too fast, too much bite and toughness. For materials with high hardness and large cross-section, slow saw blade speed and moderate feed speed are required. The saw blade is not explosive and the saw-tooth is not sharp. The sawtooth is too blunt to increase the cutting load, or the cut material can be loosely rotated to tear the saw. The piece, so the blade saw blade has to be re-grinded incorrectly.

Improper number of teeth According to the actual choice of different tooth types and number of teeth, can not be a tooth type or number of saw blades to cut any material cutting oil is not or insufficient to check the machine is cut material is too shaped or too long to shake the special shaped fixture to do special.

Previous: dekton cutting blade