Tuck point saw blade suppliers

Time:2019-03-11 15:22:03Browse:0

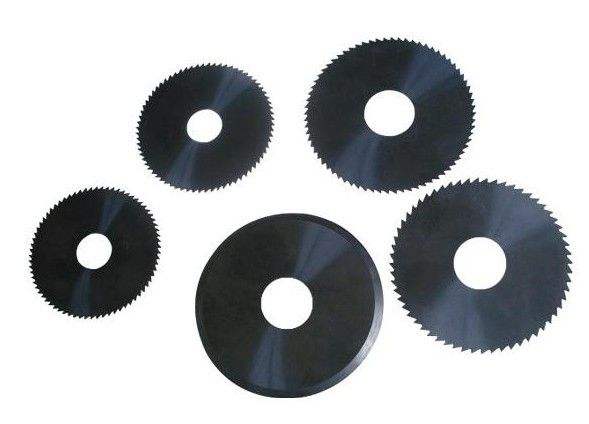

The most important part of the mechanical operation of a multi-blade saw is the saw blade. The quality of the saw blade affects the use of the multi-blade saw. Use the saw blade for frequent maintenance. Let me give you a few examples of maintenance:

1. The saw blade finds sound and abnormal vibration during work, and produces odor. It is necessary to stop the operation immediately, check it in time, and eliminate the fault to avoid accidents.we are provide dekton cutting blade,you can know it.We can guarantee the quality of dekton cutting blade.

2. During the use of the saw blade, the saw blade becomes unsharp and should be trimmed in time. Otherwise, the cutting effect will be greatly affected, resulting in shortened service life of the saw blade. The saw blade should be ground on a professional gear grinding machine. It is not possible to change the original angle of the saw blade to avoid breaking the dynamic balance.

3. Ensure that there is no excessive gap between the inner diameter of the saw blade and the shaft diameter of the machine. Install the specification sleeve and tighten the nut.

Important reminder: Saw blades are recommended for use on multi-blade saws.

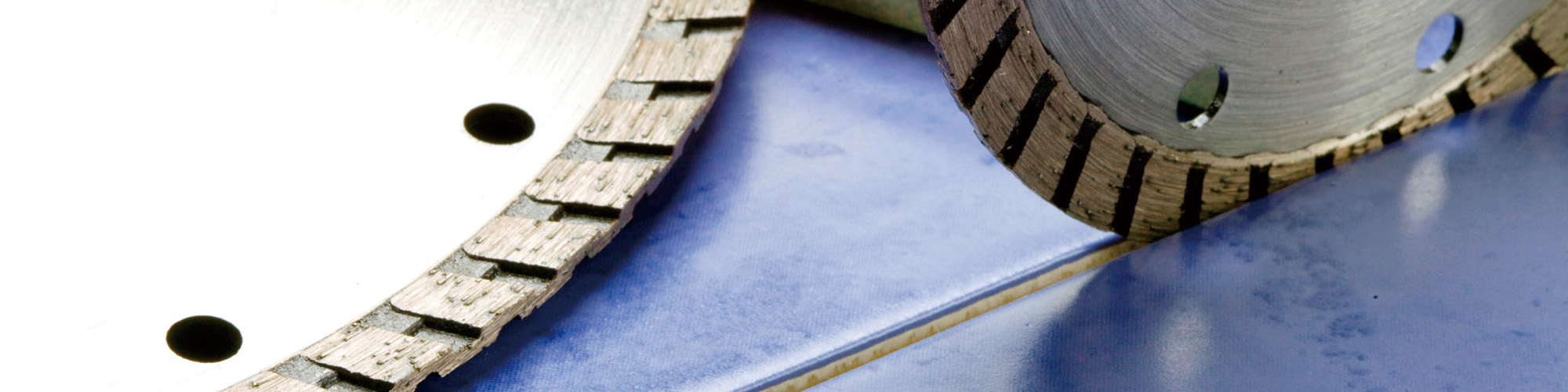

The saw blade with the scraper does not deform during use, the cutting surface is smooth, and the wood chips are taken out to ensure the heat dissipation of the saw blade to prolong the service life.

Continuous technological innovation and reliable product quality are the basis of Walter's tools. The company relies on high-end talents, develops advanced technology, introduces the latest equipment, implements scientific management, and continuously introduces new products to meet market needs to the utmost.