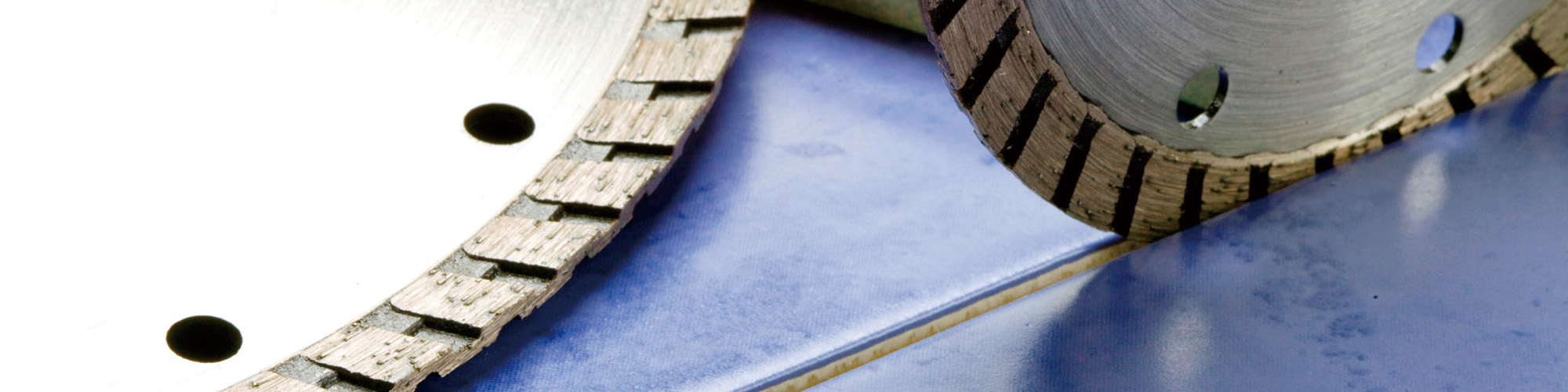

Design Principle of Diamond Saw Blade

Time:2019-02-20 10:10:02Browse:0

The design principle of diamond saw blade is that diamond saw blade is a special powder metallurgical product processed from diamond and metal powder. Some methods and means of conventional powder cerium flash are used for reference in manufacturing diamond saw blade.we are provide diamond cup wheel,you can know it.

This kind of saw blade can ensure the efficiency of work, but we can not absolutely guarantee the safety of users. Therefore, it is suggested that precautionary measures should be taken in the use time. However, due to the particularity of diamond and the complexity and variability of processing objects, it is more difficult to measure it by mechanical properties standards than ordinary powder flash cerium products.

Binder is the most important factor affecting the performance of tool head.

Diamond saw blade binder:

Selection of saw blade binder in production research needs to be considered

(1) diamond control ability;

(2) Synchronized wear of diamond and binder for different processing objects;

(3) Suitable manufacturing conditions;

(4) Reasonable cost. The binder has mechanical and chemical control over diamond. The mechanical holding force is mainly determined by the elastic modulus of the binder. Elements such as Cr, Mn, W or WC hard phase can increase the holding force and wear resistance. Of course, too high wear resistance is not conducive to diamond cutting edge. Chemical holding force is formed by "welding" or chemical bonding between diamond and binder.

If the saw blade is blunt, it should be grinded immediately and the original cutting angle of the saw teeth should be kept.

When grinding, not only appropriate diamond grinding wheel should be selected, but also coolant should be used.

It is suggested that the hole enlargement of saw blade should not exceed 20 mm of original hole. Otherwise, it will cause tension loss and the cutting effect of saw blade will be affected.

Every installation must ensure that flange and gasket are clean and flat.

When grinding back angle and saw body, be careful not to operate by hand, which will cause saw teeth splitting and unbalanced saw body.

When installing row saw, pay attention to the same level of iron frame and material table.

Before cutting, check that the saw blade is firmly installed to prevent the blade from slipping on the axle.