Matters needing attention in marble saw blade cutting

Time:2019-02-13 11:53:02Browse:0

Install the slice on the cutting machine, adjust the cutting depth, place the artificial marble on the working table, determine the size and start cutting.

Now the artificial marble is flattened, measured with a ruler and drew lines, then installed the stone cutting pieces, cut slowly from the line, it is necessary to use mineral water bottles to increase efficiency.

Whether the hardness of the matrix is up to the standard or not directly affects the use. It is a good saw blade that the matrix has the characteristics of no distortion under high temperature welding and no distortion under force majeure conditions.

* Step by step to see the color of the knife head. The marble saw blade cuts the stone, and the knife head plays a direct role. Unlike granite saw blades, marble saw blades are usually brass-colored or reddish, but the same thing is that high-quality blades are "clean", that is, they do not give people a dark feeling.

The more "dry and quiet", the better the quality of raw materials used in the knife head.

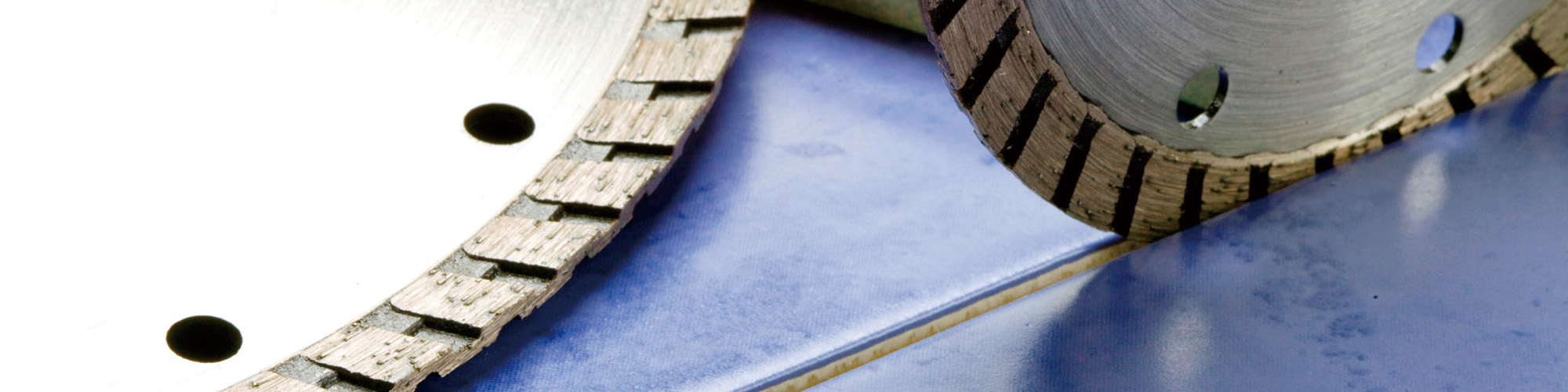

The second step is to see the appearance of the knife head. The marble saw blades manufactured by regular manufacturers have neat appearance, dimension error less than 0.1 mm, uniform thickness, sharp edges and corners, * the important thing is to give people a sense of density.

High-quality marble saw blades have higher cutting standards and contain more fine diamond particles than granite saw blades, which are shown on the blade head * Yes, after cutting, the comet tail of diamond particles is smaller and shorter than that of granite blade, so that it gives people a sense of density. The size error of marble saw blades in silver sky is less than 0.05 mm.