How to carry out the circular blade position adjustment of the slitter

Time:2019-01-29 09:36:01Browse:0

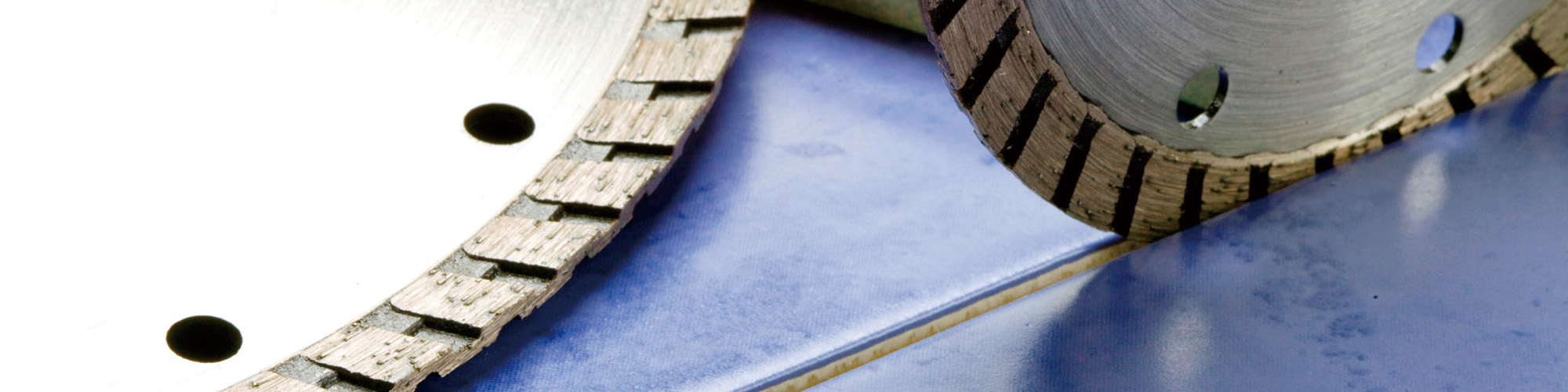

After the blade of the slitter is adjusted, the blade of the slitting machine is slowly placed into the sipe, and the depth is 3~5mm. The slitting blade must be in the sipe base, and it is not illegal. The two can't touch, otherwise the blade will be turned on. The thin blade is burned out in conflict with the sipe.we are provide tuck point saw blade,you can know it.

In production

The blade of the slitter blade is grounded every 200~50mm according to the quality. It is advisable to cut off the paper and cut off the bright and beautiful. Pay attention to the foreign objects such as the paper edge. Do not roll into the blade drive gear to avoid damage to the machine. At the end of production, the paper dust and oil on the equipment will be removed in time.

In gear machining, it is necessary to calculate the minimum effective cutting length of the hob.

The shortest effective cutting length of the gear hob is the minimum axial length (L0t) min of the hob required to cut the full tooth height of the gear. In gear machining, there are many situations in which it is necessary to calculate the minimum effective cutting length of the hob. For example, when the pinion gear of the double gear is hobbed, if the pinion gear is a helical gear and is close to the large gear, it is necessary to check whether the hob will collide with the large gear when the pinion is cut. The smaller the outer diameter of the hob, the shorter the axial length and the less likely it is to collide with the large gear. However, if the outer diameter of the hob is too small, the strength of the root key groove portion will be affected (in this case, the hob and the cutter shaft can be integrated); in addition, if the axial length of the hob is too short, the complete small size may not be cut. gear. Therefore, in this case it is necessary to calculate the shortest axial length of the hob. In addition, (L0t)min is also the basis for calculating the total length of the hob tooth (considering the length of the string).