How to choose the correct saw blade?

Time:2018-12-24 14:03:12Browse:0

the basic data:

1 machine spindle speed, 2 workpiece thickness and material, 3 blade outer diameter size and aperture (shaft diameter);

2. Selection basis: Calculated by the spindle rotation number and the outer diameter of the mating saw blade. Cutting speed: V=π×outer diameter D×number of revolutions N/60 (m/s) The reasonable cutting speed is generally 60-90 m/ Second, specific recommendations: material cutting speed cork 60-90 (m / s) hardwood 50-70 (m / s) particle board, plywood 60-80 (m / s) cutting speed is too large, machine tool vibration, loud voice, saw The sheet stability is lowered, the processing quality is lowered, the cutting speed is too small, and the production efficiency is lowered. The same feed rate, the amount of cutting per tooth increases, affecting the quality of the machining and the life of the saw. Because the saw blade diameter D and the spindle rotational speed N are power functions, in practical applications, it is most economical to increase the rotational speed and reduce the saw blade diameter.We are provide ceramic tiles cutting blade cheap,you can buy it.

3, the price-to-price ratio: As the saying goes: "Cheap is not good, good goods are not cheap", may be correct for other goods, but for the tooling tools, I am afraid not to be the same; the key is matching. Many factors on the job site: such as equipment sawing objects, quality requirements, personnel quality, etc. Conduct a comprehensive assessment, rationally choose the best use of materials, just right, to save money, reduce costs, and participate in industry competition. This depends on mastery of professional knowledge and understanding of similar

product information.

Second, the correct use: In order to make the saw blade to its best performance, it must be used in strict accordance with the specifications;1. Saw blades of different specifications and uses have different blade angles and base forms, so try to use them according to their corresponding occasions;

2. The size and shape accuracy of the spindle and the clamp of the equipment have a great influence on the use effect. Check and adjust before installing the saw blade. In particular, the factors affecting the displacement and slippage caused by the clamping surface of the splint and the saw blade must be eliminated;

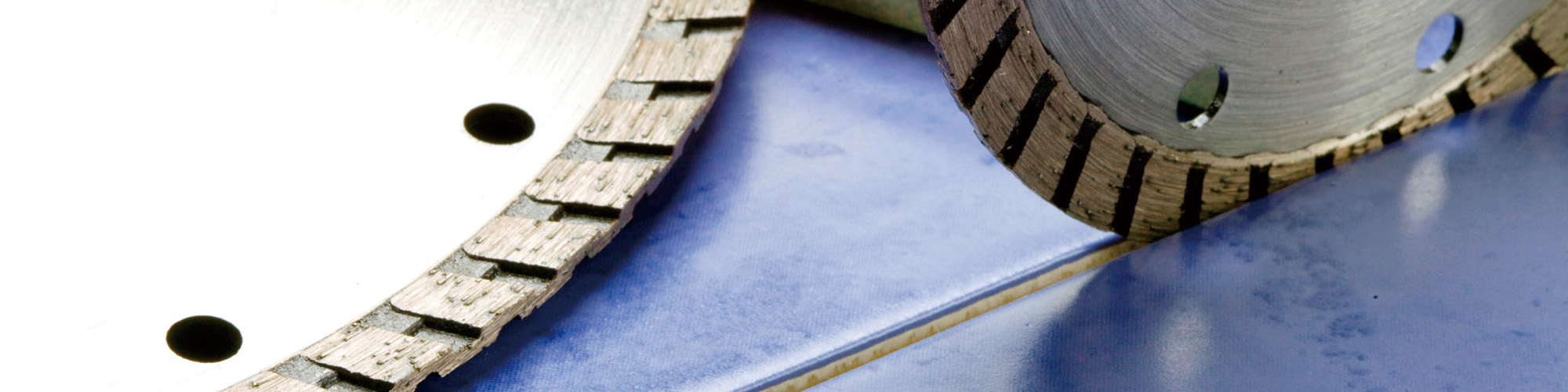

Introduction of large saw blades and small saw blades for precision panel saw blades:

In general, precision panel saws have two saw blades, one big and one small. The large saw blade is usually called the main saw blade of the panel saw. The commonly used specifications are 305*72 teeth and 305*96 teeth. The small saw blade is the scribe saw blade. The scribing saw blade is further divided into a single piece and a double piece. The popular name is also called single stroke or double stroke (double stroke is also called child mother piece).

In addition, the scribing blade is generally thicker than the main saw blade, which is more conducive to preventing the plate from collapsing.