What kind of saw blade is used for sawing tiles?

Time:2018-12-24 14:59:12Browse:0

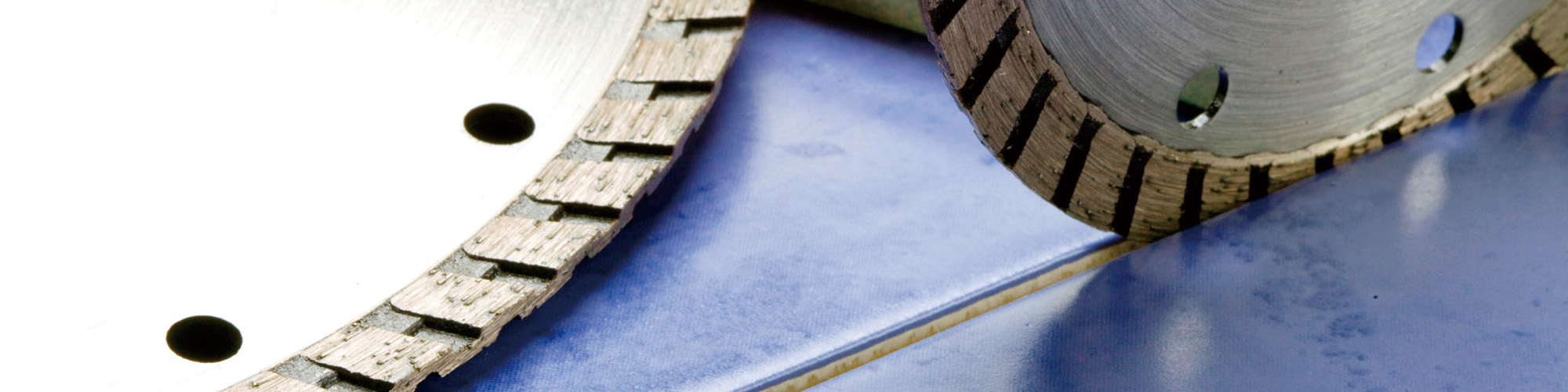

The diamond saw blade is mainly composed of two parts; the base body and the cutter head. The base body is the main support part of the bonding cutter head, and the cutter head is the part which is cut during use, the cutter head is continuously consumed in use, and the base body does not, the cutter head can cut The role is because it contains diamond, which is the hardest material at present, and it rubs and cuts the object to be processed in the cutter head. The diamond particles are wrapped in metal inside the cutter head.

We are provide ceramic tiles cutting blade cheap,you can buy it.

Features:

1. The grinding wheel has large elastic modulus, small thermal expansion, good toughness, small deformation of the grinding wheel and good shape retention, and can obtain processed parts with precise dimensions and surface finish.2. The grinding wheel has a porous internal structure. The bonding agent has a strong holding force for CBN. The cutting is sharp when grinding, the grinding force is small, the grinding wheel maintains high grinding efficiency, and the surface burn and microcrack of the workpiece are avoided. The surface of the workpiece is under compressive stress, which improves the compressive and fatigue resistance of the workpiece, and the durability of the workpiece is increased by 10%-30%.

3. The grinding wheel is sintered at high temperature, which has strong holding force on CBN abrasive grains. Therefore, the grinding wheel has an extremely long service life and the durability is 30-100 times that of the corundum grinding wheel.

4. The grinding wheel has high strength, good impact resistance, high strength of the block, and the soft elastic layer at the joint of the joint block is beneficial to the elimination of grinding stress and grinding heat, so that the grinding wheel can adapt to high speed grinding, line speed. Can reach more than 60m /s.