The design principle of diamond saw blade

Time:2018-12-07 16:55:12Browse:0

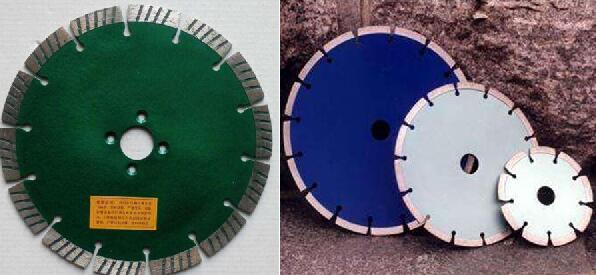

Diamond saw blade is a kind of industrial widely used processing equipment, in order to facilitate you to understand the diamond saw blade,

then we will briefly introduce the design principle of diamond saw blade.Our company can provide ultra thin diamond saw blade and ceramic cutting saw blade or stone cutting diamond saw blade,you can buy it.

The design principle of diamond saw blade, diamond saw blade is a special powder metallurgy product which is processed by diamond and metal powder.

This kind of saw blade can guarantee the efficiency of work, but we can not absolutely guarantee the safety of users,

so it is suggested that precautions should be taken in the use of time, but because of the particularity of diamond,

the complexity, and variability of processing objects, it is more difficult to measure it than the general powder flash products with mechanical properties standards.

The major factor that influences the performance of the tool head is the binder.

Diamond saw blade binder: in the production and research, the choice of saw blade binder should be considered,

(1) the ability to control diamond; (2) coordinated and synchronous wear of diamond and binder for different processing objects;

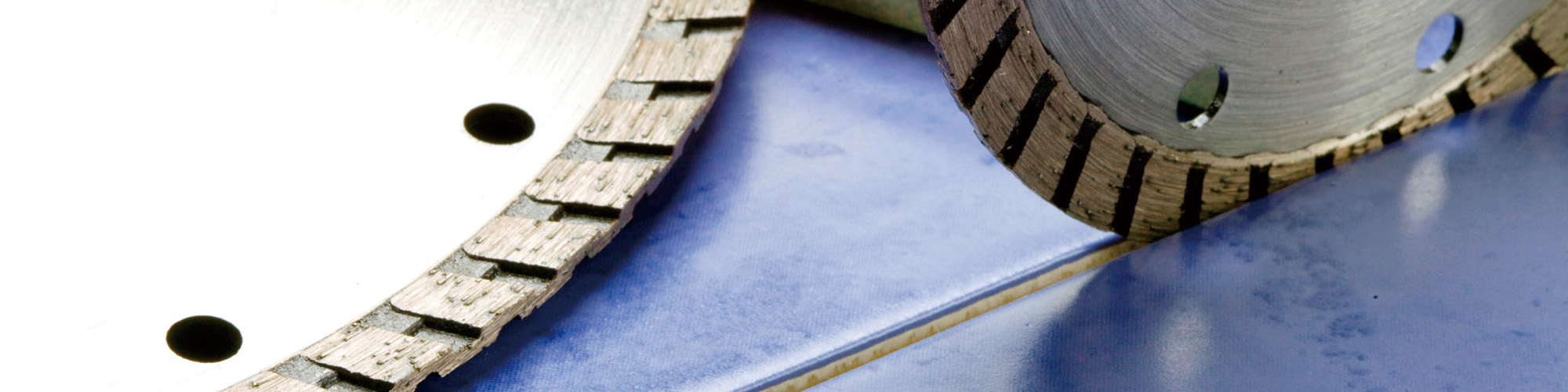

Analysis of serrated structure of diamond circular saw blade

Analysis of the sawtooth structure of diamond circular saw blade:

In the process of sawing, the blade runs at high speed, and friction and wear occur between the blade base and debris flow.

Because the radial wear and lateral wear of the joint are not consistent, when the working layer of the joint will be exhausted,

the friction between the saw blade matrix and cuttings will increase, resulting in "clamping saw",

which will cause the wear and deformation of the saw blade matrix and reduce the number of reusable matrix.

Therefore, the following measures can be taken to protect the matrix.

1) use the method of electric welding to weld hard particles on the saw blade matrix in uniform circular direction and staggered radial direction (see figure 1).

This method can reduce the wear of debris flow on the side of the matrix, but it will increase the manufacturing cost of the matrix and the difficulty of matrix deformation correction.

2) a layer of wc-co as the main component is sprayed on the side of the substrate of the saw blade by low-temperature spray method (see figure 2).

This method can not only prevent side wear but also improve the rigidity of saw blade. Such as Ø with diameter 323 mm diamond circular saw blade sawing concrete pavement (saw blade speed of 2400 r/min,

cutting depth 60 mm, feed speed of 3 m/min), spraying after the spray layer the service life of the saw blade can be increased from 2899 m to 4500 m.

The key to the application of this technology is to choose the best spraying process, thickness and area of the spraying layer.