Diamond saw blade technology and quality discrimination saw blade

Time:2018-12-04 14:34:12Browse:0

The use of a diamond saw blade is widely used in more and more industries. With the integration and subdivision of the industry, the classification of diamond saw blade becomes finer and finer.

Today, the classification of diamond saw blade is Shared with you.Our company can provide ultra thin diamond saw blade and ceramic cutting saw blade or stone cutting diamond saw blade,you can buy it.

I. classification of the manufacturing process:1. Sintered diamond saw blade: it is divided into cold pressure sintering and hot pressure sintering. The diamond saw blade is formed by pressing and sintering.

2. Diamond saw blade welding: there are two kinds of diamond saw blade welding: high-frequency welding and laser welding.

High-frequency welding welds the cutter head and the matrix through high temperature melting medium; laser welding welds the cutter head and the matrix through high-temperature laser beam;

laser welding melts the cutter head and the matrix contact edge through the high-temperature laser beam to form metallurgical combination.

Brazing diamond saw blade: melt the brazing filler metal with flame and infiltrate the powder of the cutting head into the matrix to make it stick firmly.

Ii. Appearance classification:

1. Continuous edge saw blade: continuous serrated diamond saw blade is generally made by sintering.

The bronze binder is commonly used as the basic tire material. And use a laser to cut the type of slit.

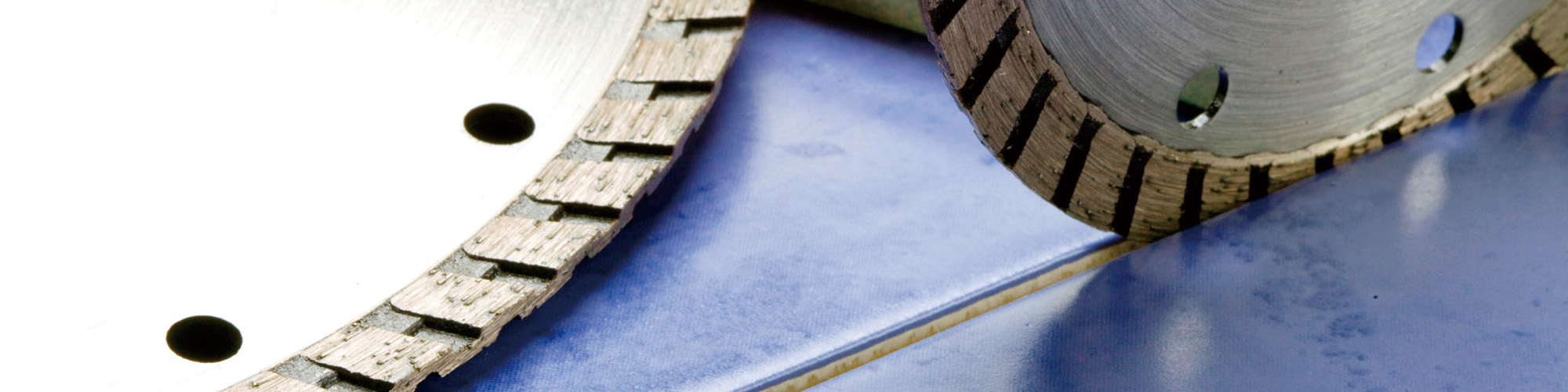

2. Knife-head saw blade: the saw blade is disconnected with fast cutting speed, suitable for dry and wet cutting methods.3. Turbine-type saw blade: combining the advantages of the previous 1 and 2 items,

the serrated blade presents uniform turbine-shaped convex and concave continuously, which improves the cutting speed and increases the service life.

Different kinds of diamond saw blades are selected for different materials, and different powder formulations are suitable for the characteristics of different materials,

which have a direct impact on the quality, effect, pass rate and cost and benefit of material products.

Diamond circular saw blade is the most ideal stone cutting tool at present. Today will explain to you, from which several aspects to distinguish the quality of the saw blade.Quality and design principle of diamond saw blade

Along with the stone material processing factory to the production, efficiency pursue,

as well as the people to the stone material processing quality request is higher and higher, the saw blade sharpness, therefore, more and more receives the attention.

A survey of the Chinese stone cutting tools market, there are many manufacturers of diamond saw blade under the banner of "the sharpest diamond saw blade", but the quality simply cannot stand the test of the market.

The safety performance of diamond saw blade is a quality problem that cannot be ignored because the "tooth loss" caused by production reasons or use reasons directly affects the performance of the saw blade and the personal safety of the operator. In industrial production, diamond saw blade tools have some dangers when used. Due to the protection and attention to life, their safety has been paid more and more attention by manufacturers and users. Although national standards and industry standards have not the safety properties of the diamond saw blade to make specific provisions, however, can draw lessons from relevant international standards, such as new EN13236 standard and foreign recall problem reported cases, improve production technology, perfect monitoring method, so as to ensure the safety performance of diamond saw blade.