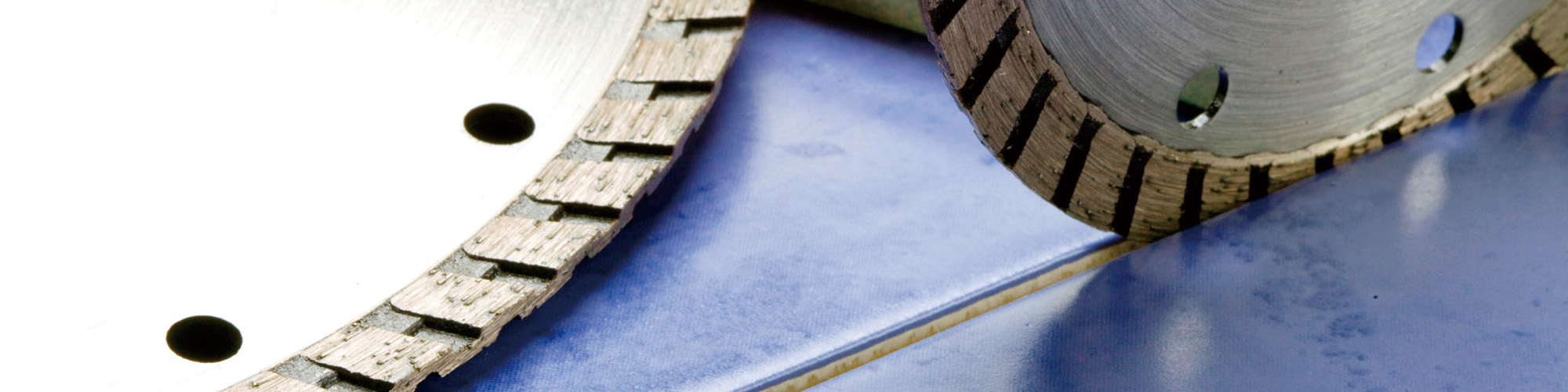

Vertical green brick cutter saw blade and saw blade difference

Time:2018-11-24 09:39:11Browse:0

Vertical environmental protection brick cutting machine saw blade and saw blade difference: saw blade thickness thin, small saw path,

small dust, thick saw blade thickness, big saw path,

big dust Aerated brick concrete cutting machine can adopt different processes for

production according to the types of raw materials, quality and technological

characteristics of main equipment. But in general, the fly ash or silica sand and

water into slurry, adding powdered lime, cement, gypsum and foaming agent, after

classics agitate injection mould box, static oxygen foaming after curing, cutting into

various specifications block or plate, the steam car ownership into autoclaved kettle,

under the high temperature of saturated steam curing the formation of porous lightweight aerated concrete products.

Our company can provide brick cutting saw blade you can buy it.

1. Before use, check that the power supply

voltage should be within 10% of the rated value, and the switch should be disconnected before switching on the power supply.

2. Carefully check whether the saw blade is cracked or damaged before use. If so, please replace it immediately.

3, check the saw blade into the working state, non-friction table and speed of steady before starting cutting operations.

4, work feeding requirements should be stable not too hard, such as the saw blade speed sharply down should reduce the feeding force,

in order to prevent overload damage to the machine.

1, the machine has the direction, is strictly prohibited to reverse, otherwise it will cause damage to the machine and personal safety.

2. When the machine is in operation, the fuselage must be grounded, and it is

strictly prohibited to work off the ground.

3. Clean up the workbench in time after the machine stops.

4. Strictly prevent heavy objects from hitting the working table.

5. When the machine is not used for a long time, it should be stored in a dry and

clean place.

The new vertical saw blade cutting machine cuts bricks quickly

Use method set up two splint around one, the work surface, right splint on two rings bolts on the workbench,

when the two bolts in * outside the two bolt holes, about plywood with block can cut two pieces of 30 cm wide,

when the bolt on to the second hole, can cut two pieces of 50 cm wide block,

when the bolt in a 3 hole can cut two pieces of 20 cm wide block. On the left side of the plywood by turning the handwheel to intensify or relax block.

Note for the vertical aerated block cutting machine: this machine is strictly forbidden to reverse operation, always clean up the dust on the big wheel, long time don't clean up,

the thicker the above dust, will cause the saw blade fracture, often clean up the dust at the bottom of the machine,

after receipt of the goods should be paid attention to: three-phase power L1L2L3 position, the machine have the function of reverse protection,

if the machine does not start shall be any two phase of the three-phase power supply cord line position to exchange,

to ensure that the forward to start at the bottom of the machine has two adjustable anchor: if it is found that uneven machine, need to adjust the height of the foundation,

use until the machine to operate smoothly, also have anti-vibration rubber foot.

As a leading manufacturer and supplier in professional diamond tools, the company specialized in producing and developing all kinds of diamond tools, such as cutting tools,grinding tools and drill bits,etc.