Know the saw blade and understand how it is used and maintained

Time:2019-04-22 14:53:04Browse:0

Alloy saw blade tooth profile introduction Alloy saw blade purchase strategy

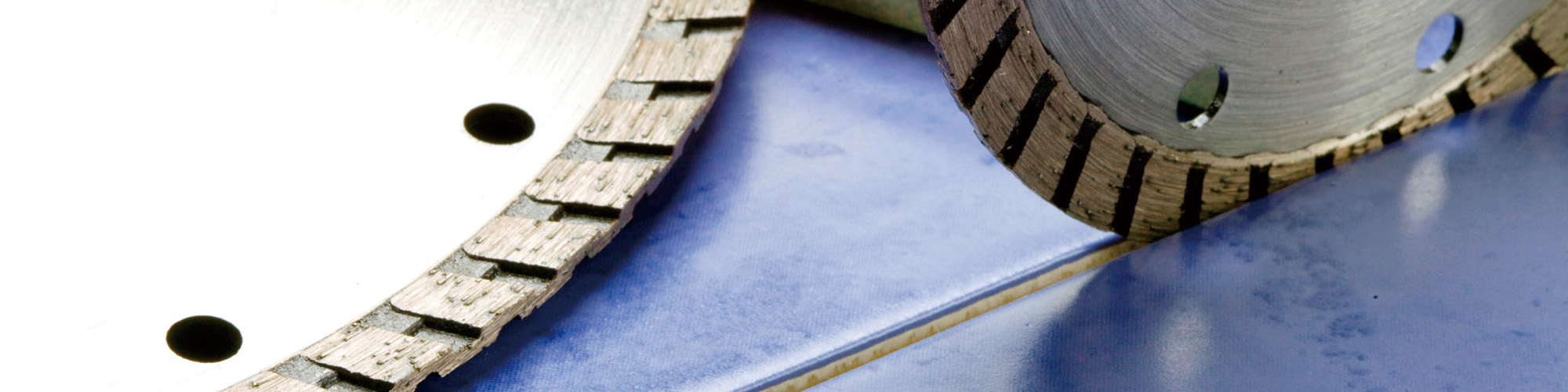

The commonly used tooth shapes of alloy saw blades include left and right teeth (alternating teeth), flat teeth, flat teeth (high and low teeth), inverted trapezoidal teeth (reverse tapered teeth), dovetail teeth (camb teeth), and rare industries. Three left and one right, flat left and right flat teeth, etc.we are provide tuck point saw blade and granite turbo cup wheel,you can know it.

1.The left and right teeth are the most widely used, the cutting speed is fast, and the grinding is relatively simple. Applicable to all kinds of soft and hard solid wood profiles and MDF, multi-layer boards, particleboards, etc. for cutting and cross-cutting. The left and right teeth with anti-rebound force protection teeth are swallow-tail teeth, suitable for longitudinal cutting of various boards with tree knots; left and right tooth saw blades with negative rake angle are usually used for sticking due to sharp saw teeth and good sawing quality. The sawing of the panel.

2.The flat tooth saw is rough, the cutting speed is slow, and the grinding is the simplest. Mainly used for sawing of ordinary wood, low cost, mostly used for aluminum saw blades with small diameter to keep the adhesion reduced during cutting, or used to slot the saw blade to keep the bottom of the groove flat.

3.The flat teeth are a combination of trapezoidal teeth and flat teeth. The grinding is more complicated. The sawing can reduce the cracking of the veneer. It is suitable for the sawing of various single and double veneer wood-based panels and fireproof panels. In order to prevent adhesion, the aluminum saw blade also uses a saw blade having a large number of teeth of the flat teeth.

4.The inverted ladder teeth are often used in the saw blade bottom slot saw blade. When sawing the double-faced wood-based panel, the slot saw adjusts the thickness to complete the bottom slotting processing, and then the main saw completes the sawing of the panel. Prevent the chipping of the kerf.

Material

Depending on the material being cut, the saw blades are made of different materials and can be generally divided into high-speed steel saw blades (HSS saw blades), carbide saw blades, insert alloy saw blades, and diamond saw blades. Woodworking saw blades are generally selected from carbide saw blades, which are the most commonly used cutting tools for wood products. The quality of carbide saw blades is closely related to the quality of processed products.

We have been developing for many years and know that corporate brands are hard to come by. In order to better serve the new and old customers and improve the brand awareness, it has been promoted and sold on the Internet. I hope that all new and old customers can call us to order!

The commonly used tooth shapes of alloy saw blades include left and right teeth (alternating teeth), flat teeth, flat teeth (high and low teeth), inverted trapezoidal teeth (reverse tapered teeth), dovetail teeth (camb teeth), and rare industries. Three left and one right, flat left and right flat teeth, etc.we are provide tuck point saw blade and granite turbo cup wheel,you can know it.

1.The left and right teeth are the most widely used, the cutting speed is fast, and the grinding is relatively simple. Applicable to all kinds of soft and hard solid wood profiles and MDF, multi-layer boards, particleboards, etc. for cutting and cross-cutting. The left and right teeth with anti-rebound force protection teeth are swallow-tail teeth, suitable for longitudinal cutting of various boards with tree knots; left and right tooth saw blades with negative rake angle are usually used for sticking due to sharp saw teeth and good sawing quality. The sawing of the panel.

2.The flat tooth saw is rough, the cutting speed is slow, and the grinding is the simplest. Mainly used for sawing of ordinary wood, low cost, mostly used for aluminum saw blades with small diameter to keep the adhesion reduced during cutting, or used to slot the saw blade to keep the bottom of the groove flat.

3.The flat teeth are a combination of trapezoidal teeth and flat teeth. The grinding is more complicated. The sawing can reduce the cracking of the veneer. It is suitable for the sawing of various single and double veneer wood-based panels and fireproof panels. In order to prevent adhesion, the aluminum saw blade also uses a saw blade having a large number of teeth of the flat teeth.

4.The inverted ladder teeth are often used in the saw blade bottom slot saw blade. When sawing the double-faced wood-based panel, the slot saw adjusts the thickness to complete the bottom slotting processing, and then the main saw completes the sawing of the panel. Prevent the chipping of the kerf.

Material

Depending on the material being cut, the saw blades are made of different materials and can be generally divided into high-speed steel saw blades (HSS saw blades), carbide saw blades, insert alloy saw blades, and diamond saw blades. Woodworking saw blades are generally selected from carbide saw blades, which are the most commonly used cutting tools for wood products. The quality of carbide saw blades is closely related to the quality of processed products.

We have been developing for many years and know that corporate brands are hard to come by. In order to better serve the new and old customers and improve the brand awareness, it has been promoted and sold on the Internet. I hope that all new and old customers can call us to order!

We cherish every opportunity to work with you!