Diamond Saw Blade Manufacturers Online

Time:2018-11-05 11:39:11Browse:0

Diamond Saw Blade Manufacturers

Our Company was founded in 1998, Our company covers an area of 8 acres with building area of 1, 000 square meters.

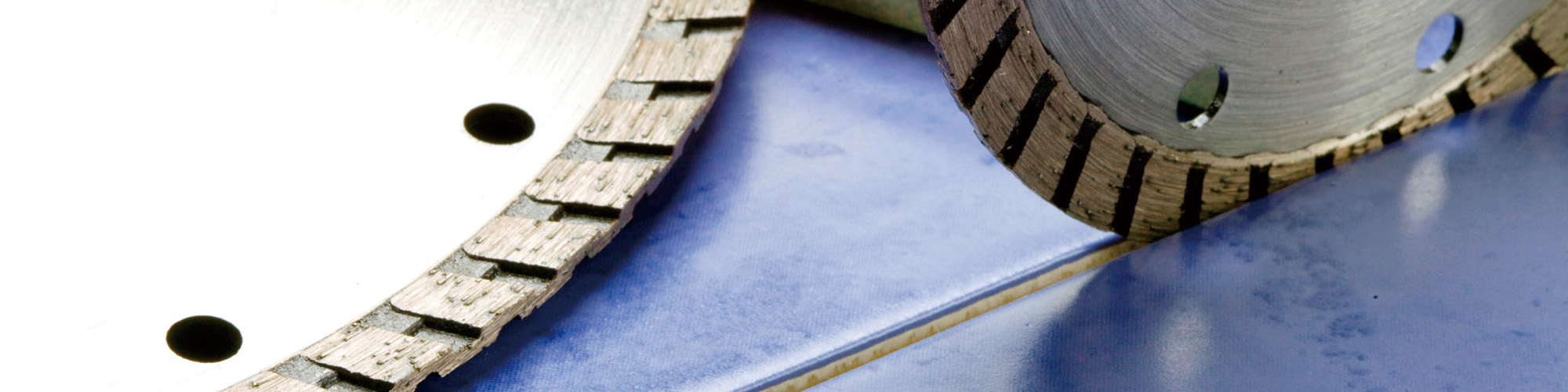

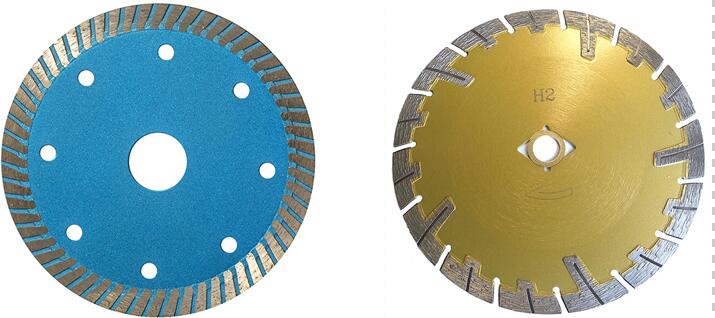

We focusing on development and producing the diamond tools. Our products are widely used in cutting the stone,

the wood, the aluminum, the tiles,the concrete and also can be used for cutting the engineering drilling concrete, the stone polishing,

the green asphalt,granite marble and any others construction materials.

Our products own top quality in the diamond tools industry. Our diamond tools are sharp, fast and stable when you are cutting any kind of materials.

1. Heat causes breakdown of the bond and rapid wheel breakdown. The heat is caused by too fast a feed and too much wheel contact.

Wet grinding helps this problem, but the main thing is to let the wheel cut without forcing it too much.

2. Dry grinding causes more wear than wet grinding, so if you are dry grinding you must grind slower in order to keep your wear down.

3. The grit size of the diamond makes a big difference in wear and stock removal.

The coarser grits yield rougher finishes but stay in the bond better and remove stock faster and cooler.

4. Diamond wheels sometimes load due to improper use and can act dull and grind very hot.

Wheel dressing will remove this build up but it is wasteful and should not be necessary if the correct wheel is used on the job.

If wheels must be dressed, the dressing should be done carefully so as to avoid excessive diamond loss.

A good rule of thumb to use for arriving at end cost is to have your labor cost equal your diamond wheel cost. This is an easy way of determining the efficiency of your operation.

Diamonds are a man's best friend when grinding a carbide saw, but you cannot do a good job in a minimum amount of time without using some diamond to do it.

Just be sure that you do a first class job and can make a profit using labor and diamonds in relation to the price of the job.

Previous: turbo rim cutting wheel