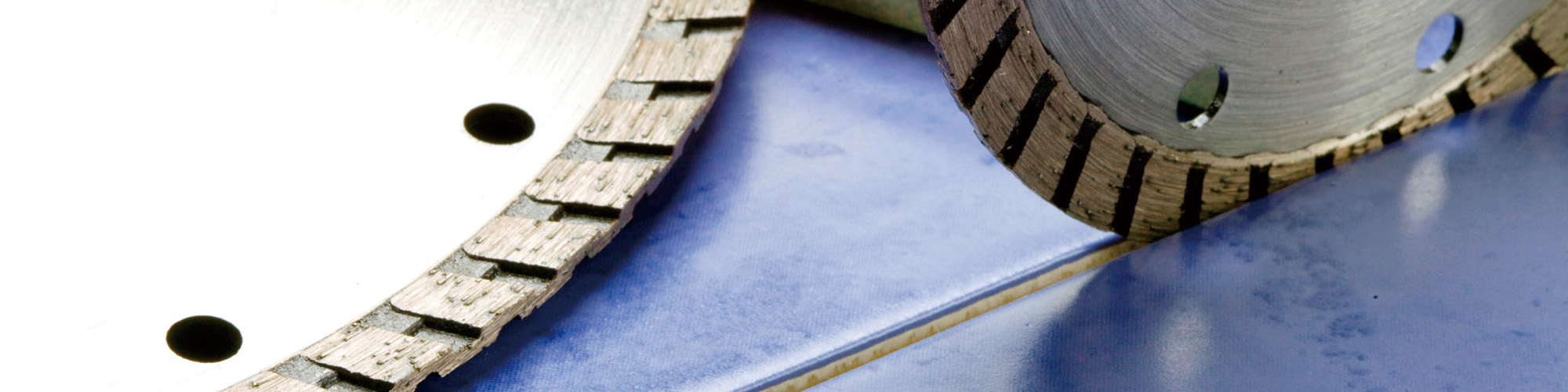

Tuck Point Blade

Time:2018-05-24 17:50:05Browse:12

·Used for concrete and other construction materials.

·The tuck point blade can cut fast and leave a clean groove on building surface, floors and walls etc.

·Use dry or wet.

Grinding and maintenance of saw blades

When purchasing the saw blade manufacturer's products, different saw blades should be selected according to the sawing direction, processing object and application occasions, and reasonable tooth number and tooth shape should be selected to ensure the sawtooth hardness, impact toughness, and cutting ability. Technical properties such as wear resistance.

In fact, improve the cutting quality of the workpiece, extend the durability of the circular saw blade and ensure the impact toughness and sharpness of the sawtooth; the size of the sawtooth has been scientifically calculated to minimize the welding residual stress, without false welding and desoldering. .

After the saw blade is used, the sawtooth has a chipping edge; the surface of the workpiece is fluffed; the sawing power is sharply increased. In order to ensure the quality and safety of the sawing, the skilled operator must re-grind and clean the circular saw blade in time and regularly remove the dirt on the serrated surface.

Through the understanding of the grinding and maintenance information of the saw blade manufacturers, we can help us better understand the performance of the saw blade and make the use of the saw blade get the best application effect, which is more favored by users.

When using the saw blade, make sure that the saw blade has been fixed. It is also necessary to match the direction of the knife when positioning the profile. Only in this way can the abnormal cut-in situation be prevented, and during use, It is not possible to apply side pressure, and in the process of feeding, it needs to be smooth, and it is also necessary to avoid the blade impact contact with the workpiece, which will cause the saw blade to be damaged, so in the process of use, You need to pay attention to its use skills to prevent the saw blade from flying out.

Only pay attention to these, it can be used better when used, usually can not ignore its maintenance, to extend the life of the saw blade.

|

Item Number |

Diameter | Segment Height (mm) | Segment Width (mm) | Arbor(mm) |

|

TP105 |

4"/105mm |

12 | 9.5 |

20/22.23 |

| TP125 | 5"/125mm | 12 | 9.5 | 20/22.23 |

| TP180 | 7"/180mm | 12 | 9.5 | 20/22.23 |

Previous: Tuck Point Blade

Next: Tuck Point Blade